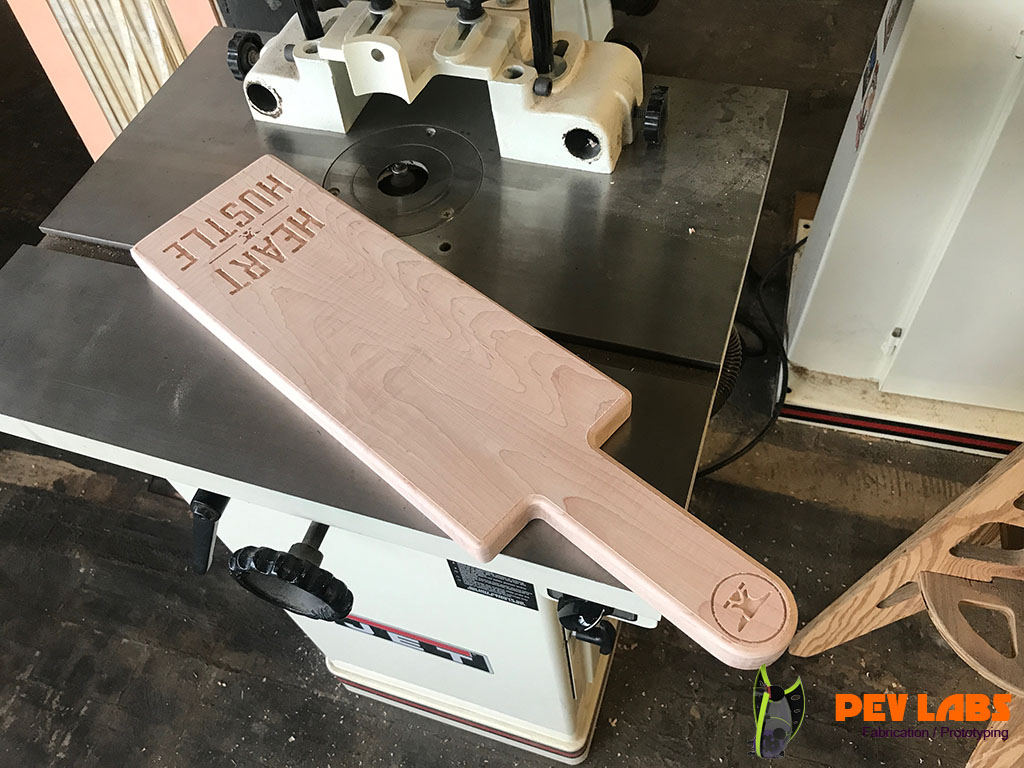

We designed and produced a few production runs of these Weightlifting Press Boards for Heart and Hustle Gym in Los Angles, CA. Project includes Product Design, CNC Milling, CNC Engraving and general Woodworking. These are made of solid hard maple grown and harvested from the eastern side of the United States. The way board presses are used in weightlifting is by Layering seven of the one inch thick boards on top each other during powerlifting training. After a set of reps are complete by the weight lifter one board is removed by the trainer which offers a new one inch lower sticking point. This is repeated until down to one of the boards. The power lifter will start with a full set of lumber between the barbell handle and the chest, working their way way down to one inch between the two. Bench Press Boards allows the lifter to focus on the lockout portion of the lift. The traditional press board method is to glue up five sets of blocks at one inch intervals. This method reduces cost by reducing material significantly and labor modestly. On the second iteration of this product we added the spine and groove to help guide the boards, or to keep them from sliding sideways. If you are in need of branded product production please reach out.

Weight Lifting Cascading Board Presses - More Digital Fabrication Videos

Weight Lifting Cascading Board Presses - 3D Modeling : We Design and Manufacture Branded Products