We design and fabricate products for clients and ourselves. Some or creations can be purchased at NotSucky.com. PEV Labs is available for hire to assist with your product designs and small production runs. We help you bring your ideas to market.

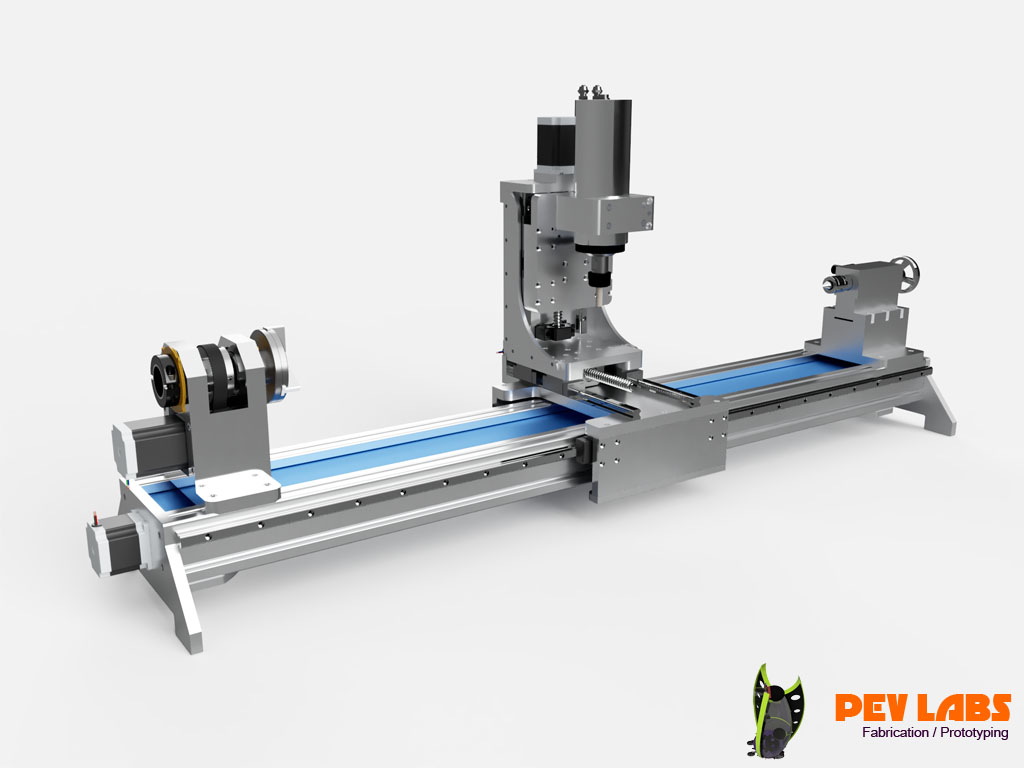

Starting with the visualization of the concept we use modern CAD / 3D modeling software to generate renderings. Tweaking the model design entails analyzing material availability, costs, labor time along with physical property attributes which effect strength and longevity. The software will generate working plans, G-Code to drive the digital fabrication equipment documentation such as BOM, or Bill of Materials. The BOM includes links to sources for all the parts outside the scope of what we make. Small run production services include fabrication, packaging when desired to drop shipping from our facility. Our fabrication competencies are fairly broad scoped. Our experiences range from creating furniture, flat pack products, beer tap handles, wooden bicycles, musical instruments to personal electric vehicles.Design is most often achieved using AutoDesk Fusion360 software which is a CAD, Parametric Modeling, Rendering, Stress Testing and CAM (Computer Aided Manufacturing) package all in one. There is excellent advantage in having the design files and manufacturing control files in on integrated solution which would be when a design element is changed there is no export and redo on the machine control. The CAM module updates on the fly since it tied directly to the CAD module. The software also provides a web viewable 3D model the client can spin around and view anywhere that has internet access.If you have a design visit our manufacturing capabilities page to learn about short run and on-demand product production.