We get many requests a week about project cost estimating. Often times the requests are lacking some information needed to for us to answer with any basic idea of a price. More about costing on this page. What we would like to achieve here is help you understand some project file requirements beneficial to us responding with pricing info. If we have to calculate and source the material needed awe might need charge for this time. On more complicated projects this can take am hour, but milling the job only takes an hour. Obviously it makes no sense to work an hour for free to land a one hour job. Thus why we push this back on the customer on small projects. For larger projects we take care of this.

Specifying Material

Please specify material. Specifics matter here. For example stating "Plywood" is not helpful in any way. There are dozens of types of plywoods with many grades of each. Preferably send a link to your material choice on your supplier website. If you don't have a supplier then we will suggest one from the material type requested.

Calculating Material

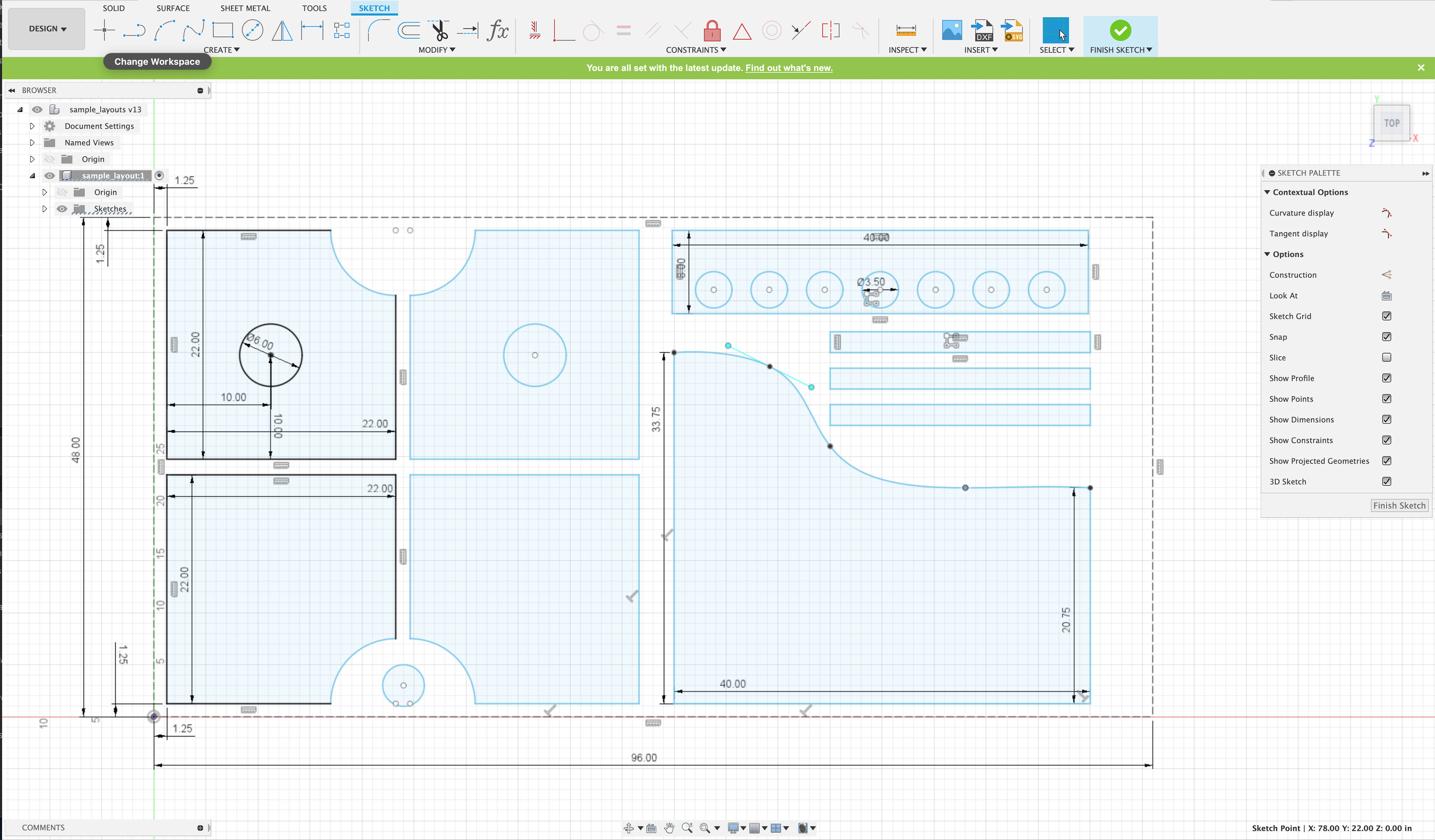

Here is a sheet stock layout example. The dashed outline is a 48x96 inch sheet goods. This lets you know how many parts will fit on a sheet. If the sheet is plywood it lets me know the direction you want the grain on each part. The grain runs the long direction. If you rotate any given part by 90 degrees then that will change the grain direction. For paint grade material this would not be important. Note I have left at least .5" spacing around the edges and between the pieces as shown here. I need room to clamp down the stock. The end mill will make the material in its path disappear. Then we need some webbing so the material does not fall apart during milling.