PEV Labs designed and manufactured a small run quantity of 25 resin cast beer tap handles for the Pro Re Nata Farm Brewery in Crozet Virginia. We designed them in AutoDesk Fusion 360. Fusion was also used to create the 3D model .stl file needed for the 3D Print used for casting. We loaded the STL into our Ultimaker 2 3D printer where we printed two different style master handles to be shown to client. Even though we were only to produce one style we sanded and primed with auto body primer both designs models. They were hot glued to a piece of plywood and formed up to make the silicon molds. Two part epoxy casting resin was mixed, degassed in a vacuum chamber and poured into the mold. This was repeated every half hour until we had 25 solid resin blanks. The indent on one side was in the mould but we had to CNC mill the other side to match. Resin mills up nicely. They were painted white. Chalk board sticker material was applied to the indents. Branding logos printed and applied to the head. Three coats of clear to seal the labels in so the would not come off in commercial use.

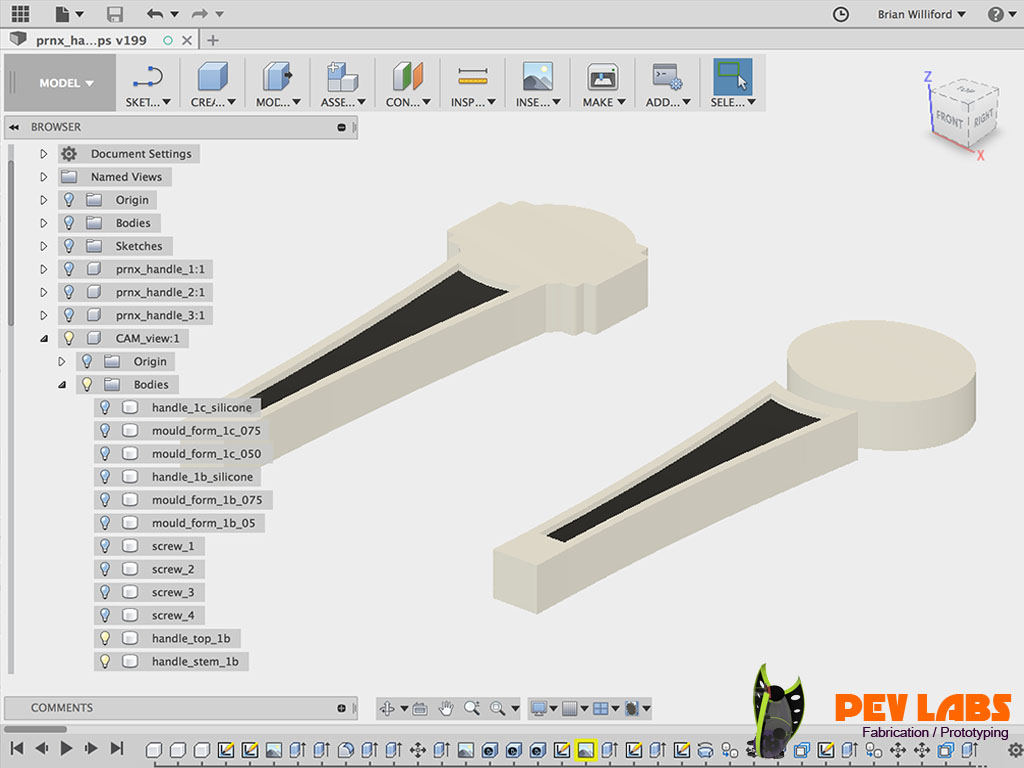

Below is an image for beer tap handles we design and manufactured for Pro Re Nata Brewery in Crozet Virginia.

3D Model of Resin Cast Tap Handle for Pro-Renata in Crozet Virginia - On-Demand Manufactured