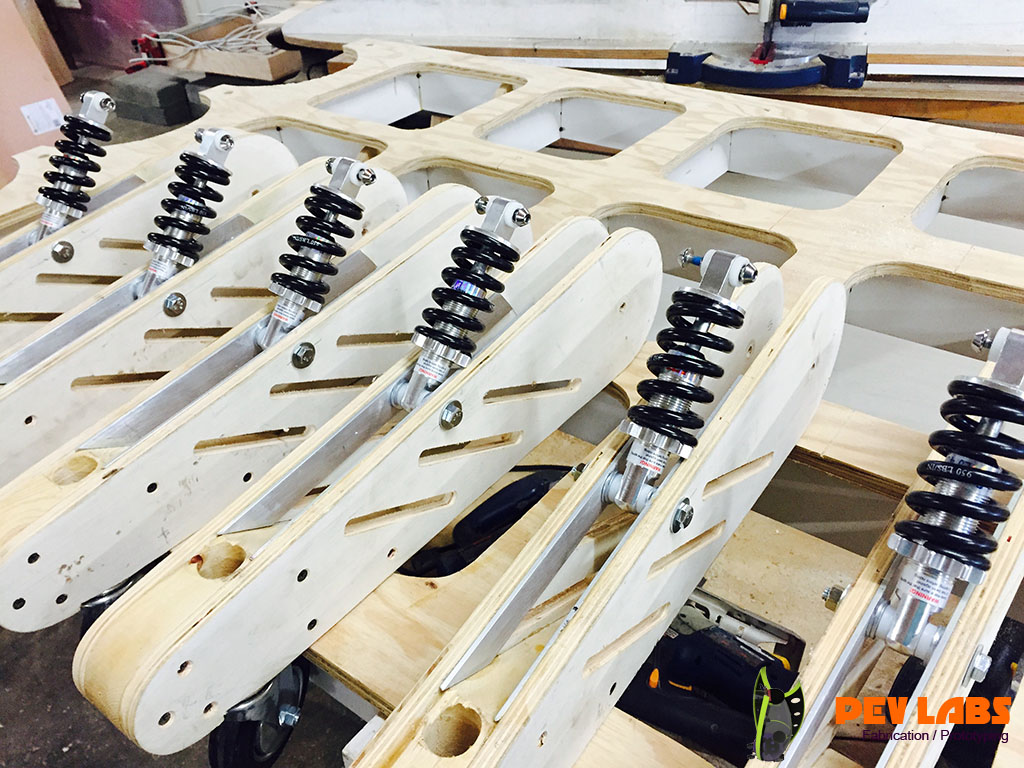

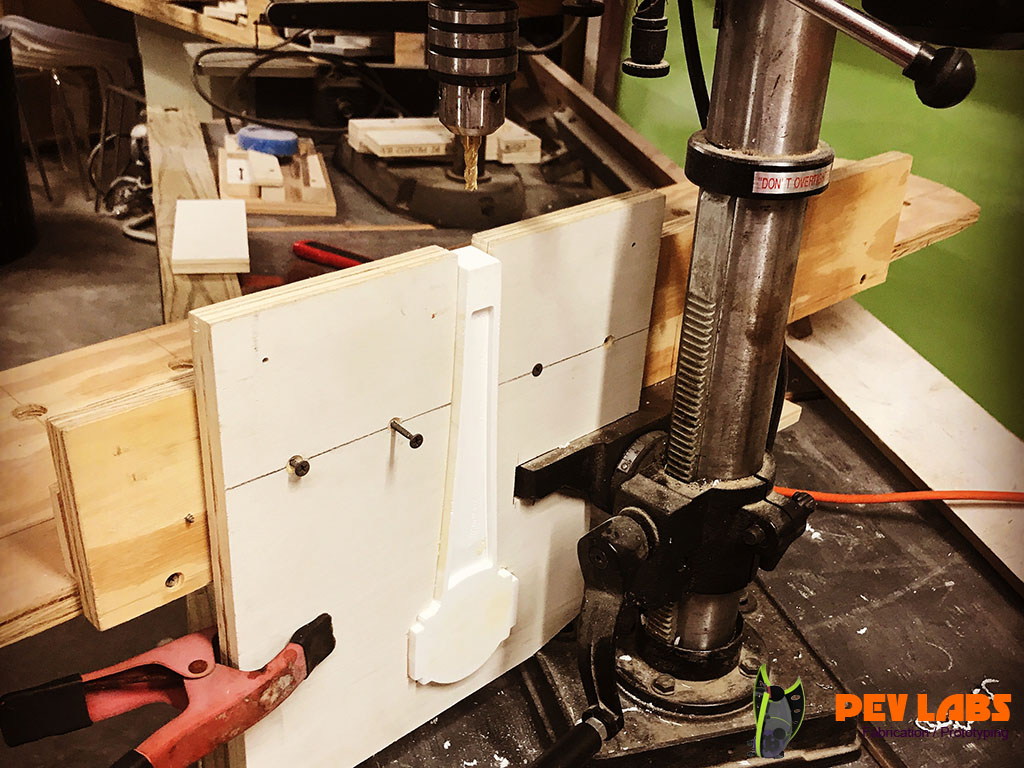

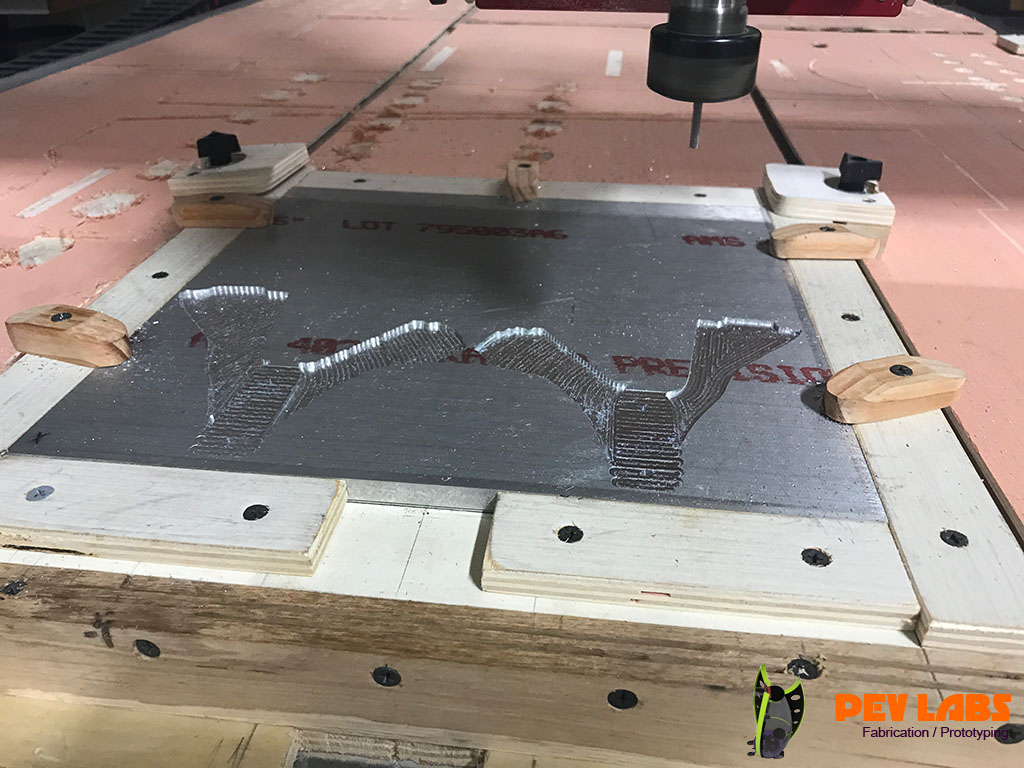

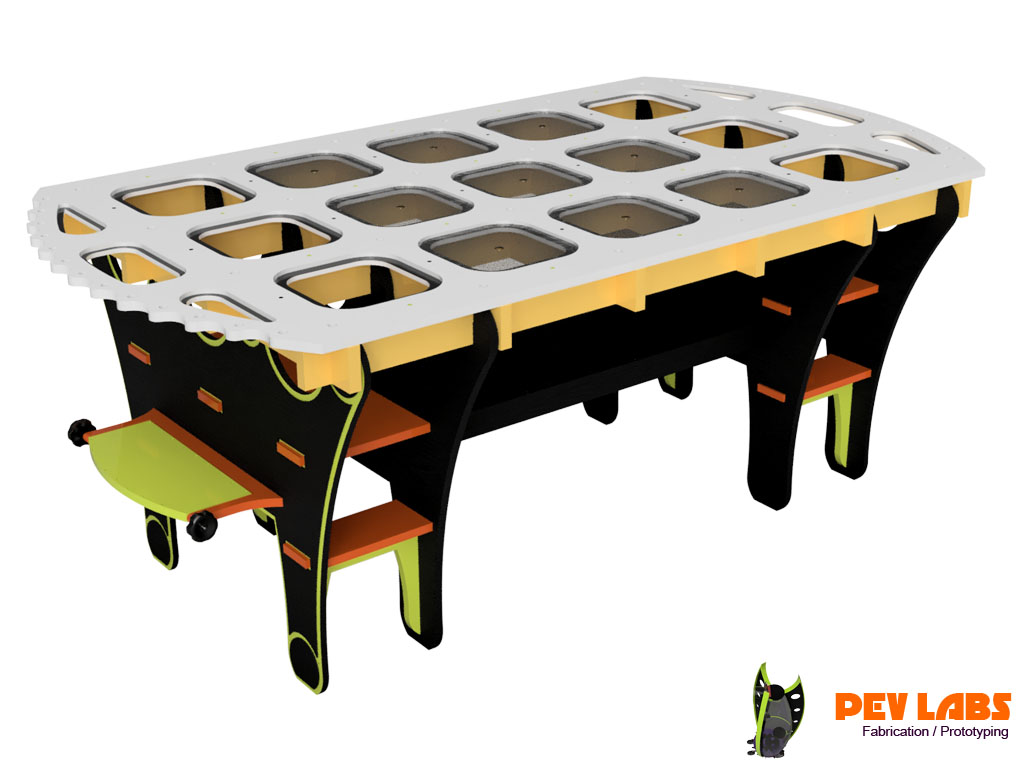

Prototyping is the process of creating a model of something from an idea. Often for feasibility testing, obtaining venture capital, shoring up a patent application or for simple visualization. Sometimes a prototype is produced simply see what something looks like in the physical sense. More often it is the early stages of product creation. Prototypes are iterated until optimal design criteria, usability, reliability and safety are achieved. This can be referred to as the product development phase. Once the alpa version is considered "close", depending on the type of product it may be necessary to hire specific engineers to certify certain competencies. Such as an electrical engineer, mechanical engineer or structural engineer. The prototyper may be more of a digital fabrication artist who is well suited in covering something in ones minds eye into an attractive physical product. Or the digital design files might go straight to a manufacturing facility for a full product production run. She or he may not have an engineering degree in every field needed to cover every idea possible, thus the reliance on shoring up design with external engineering services. In all fairness a larger firm may have all these skills on hand. Price however would certainly be reflected in the development cycle. Various tooling types may be required during product development in the making of a product prototype. These range from CNC Milling which is a form of subtractive manufacturing to 3D printing also known as additive manufacturing.

PEV Labs offers product prototyping services can help you with the design and fabrication of your idea.

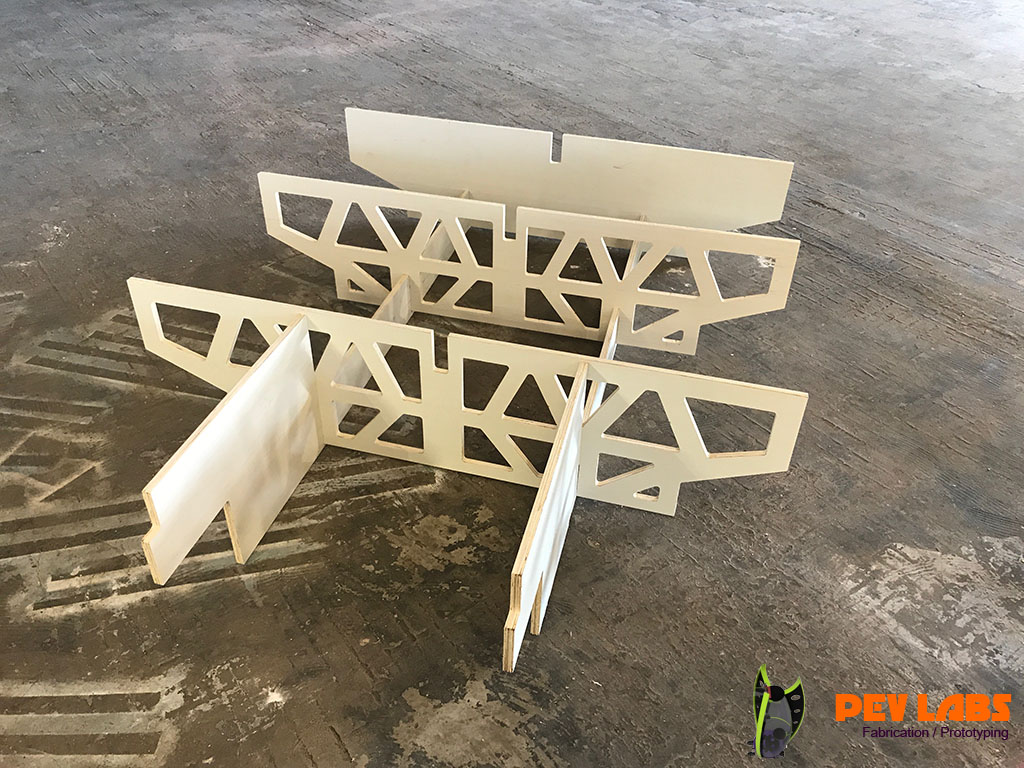

Prototyping DIY Flatpack Standing Desk Kit - More Digital Fabrication Videos

Prototyping Bespoke Electric Wooden Bicycle - More on Our Video Channel