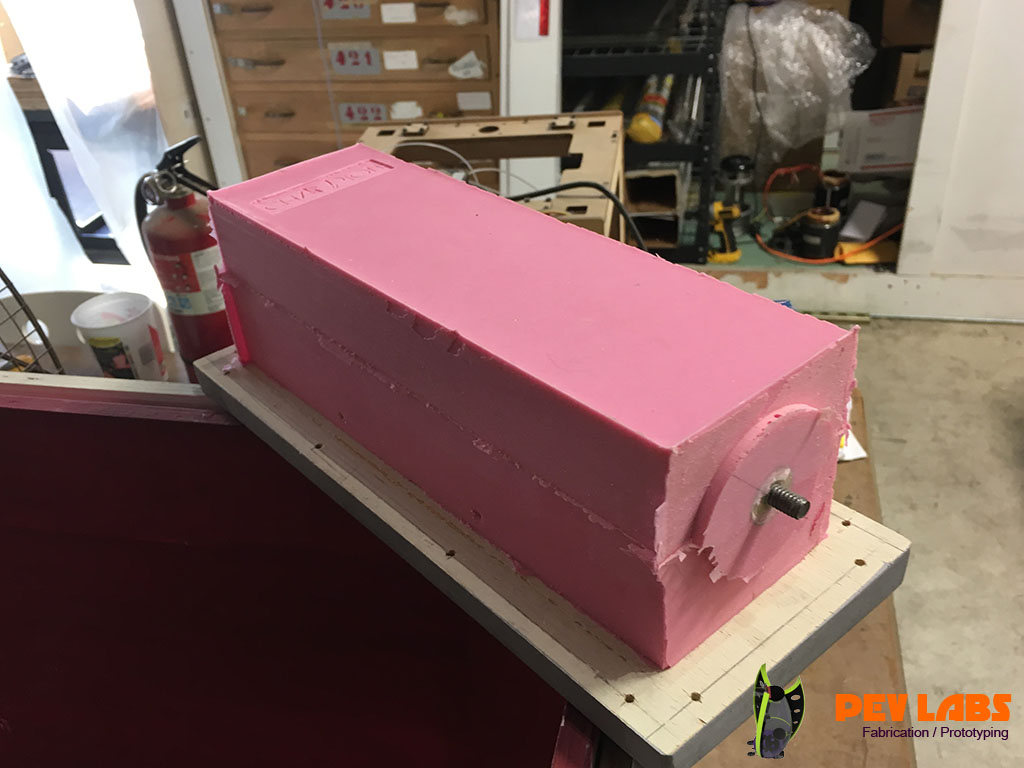

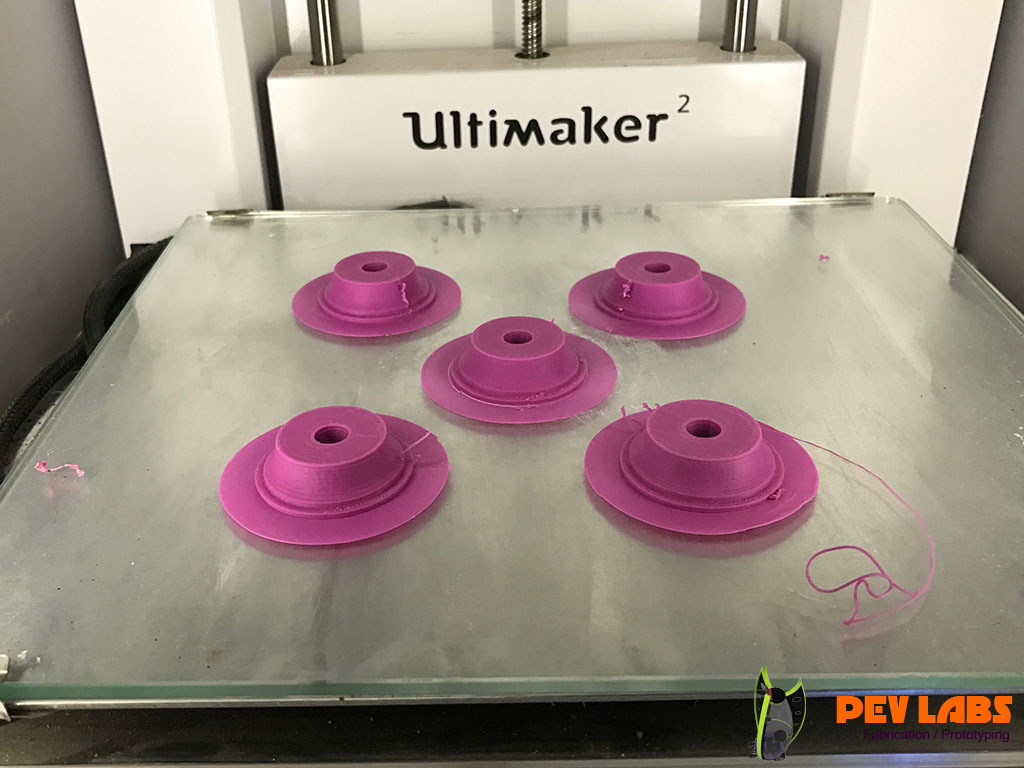

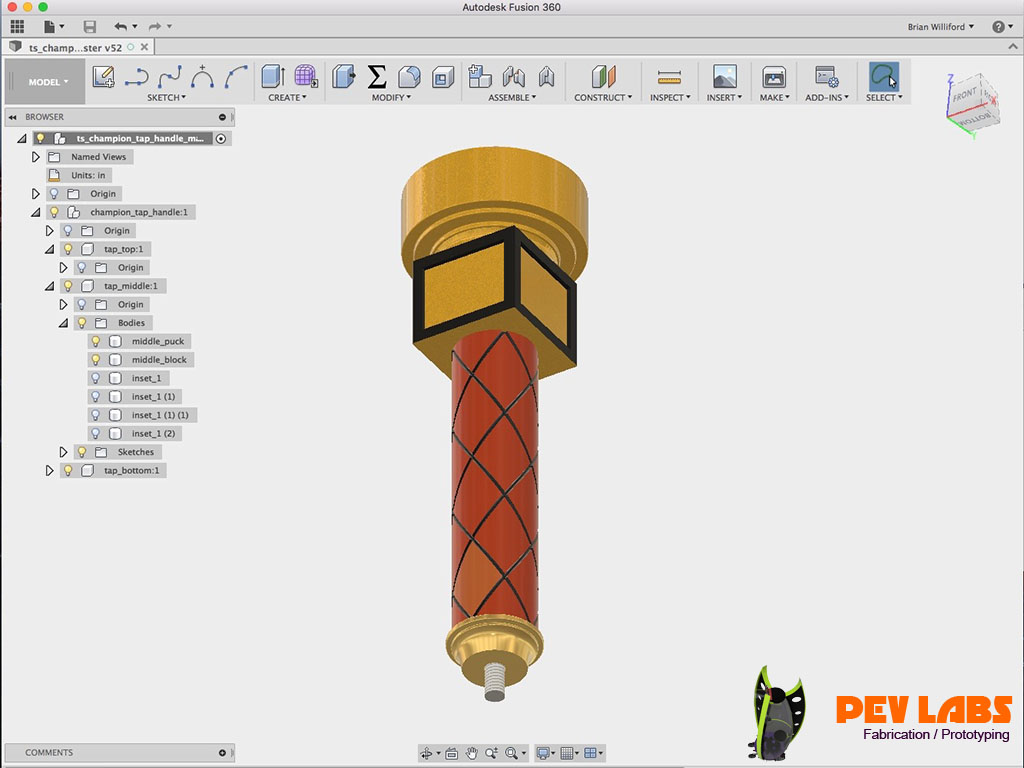

On demand manufacturing production of beer tap handles for Champion Brewing Company using 3D printing, silicon mold making and epoxy resin casting. This project requires much in the way of finishing details. Several colors of paints, some in grooves, along with thin water decals and several clear coats to seal the decals in. Given the level of detail we were unable to produce the volume needed to keep up with the company sales. Kudos to them for having an awesome in demand product! What we learned from this is our limit for tap handle contracts. As a reference we can probably do a run of 25 handles a month. We are more suitable for one offs or low volume breweries. for medium level and high volume production there are several good tap handle producers that can easily be found with a web search.

Beer Tap Handles Main Page

More about Champion Brewing Company in Charlottesville Virginia.

3D Model of Resin Cast Tap Handle for Champion Brewery in Charlottesville Virginia - Distributed Manufacturing